566 Add DPI-LCD Instance (Built-in)¶

1 Confirm rt-driver Project is Running Normally¶

It is recommended to use the rt-driver project for screen debugging. Before debugging, ensure that the rt-driver project runs normally and prints logs.

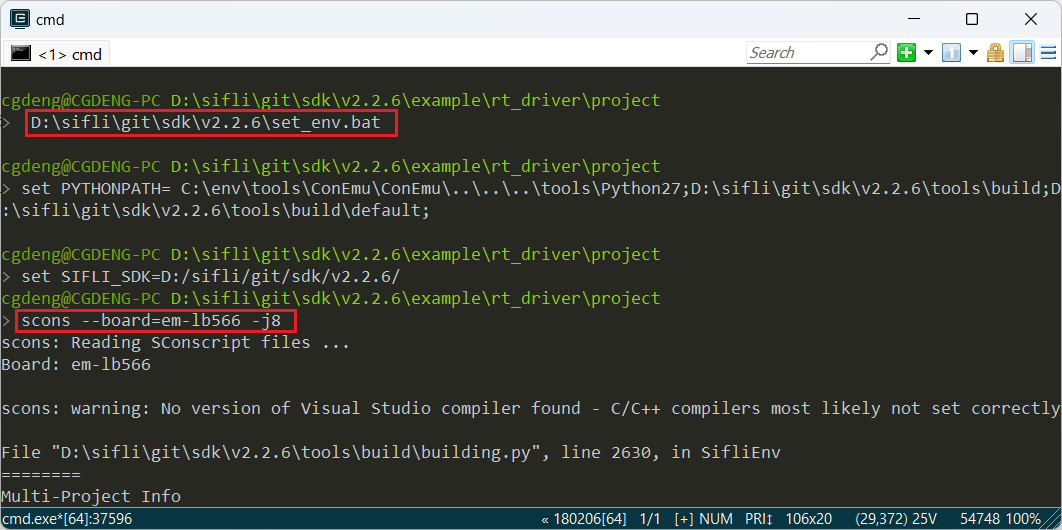

1.1 Compilation¶

Navigate to the example\rt_driver\project directory, right-click and select ComEmu_Here to pop up the compilation command line, and execute the following commands sequentially:

> D:\sifli\git\sdk\v2.2.6\set_env.bat # Set the compilation environment path

> scons --board=em-lb566 -j8 # Compile the rt-driver project for the em-lb566 module

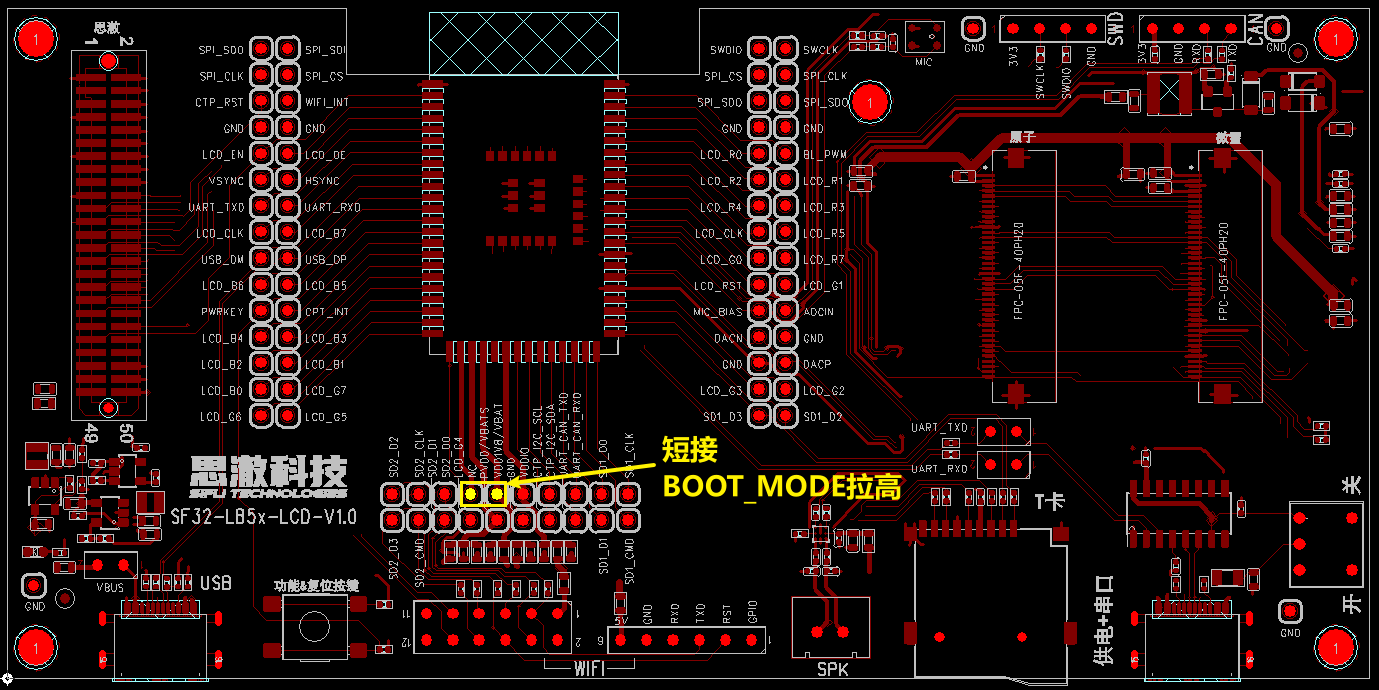

1.2 Enter BOOT Mode¶

Pull the BOOT_MODE pin high to 3.3V to enter the boot mode for easy downloading, as shown in the following figure, short the BOOT_MODE to 3.3V:

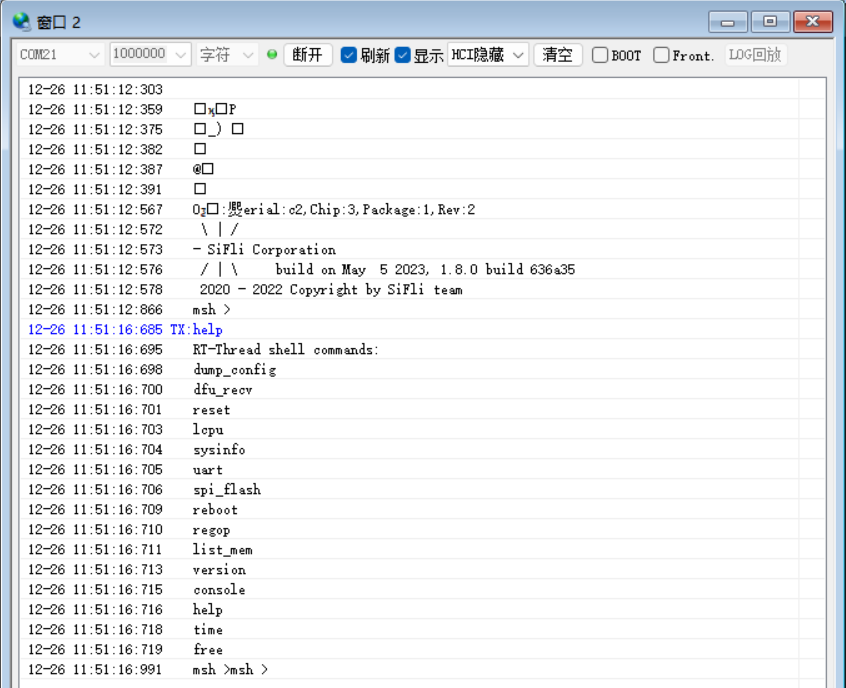

After entering the boot mode, the serial port will output the following log. Input the command help, and it will also output a log, indicating that the serial port MCU is running normally and the serial communication is working properly. Click to disconnect the serial port and prepare for downloading.

1.3 Download¶

> build_em-lb566\uart_download.bat

Uart Download

please input the serial port num:21 # then select the serial port number that can output Log in steps 1.2 for downloading

### 1.4 Confirm Normal LOG

Remove the shorting jumper from step 1.2, power on and reset, let the MCU run the user program. If the following Log is output, it indicates that the development board is running normally, and you can proceed to the next step to add a new screen module<br>

## 2 Add Screen Driver NV3052C

### 2.1 Create NV3052C Driver

1) Screen Driver Location<br>

The screen driver is located in the `sdk\customer\peripherals` directory<br>

2) Copy the Driver<br>

Copy another `dpi` interface driver and rename it to `dpi_nv3052c`<br>

### 2.2 Menuconfig Add NV3052C

1) Modify Kconfig to generate the screen option in menuconfig<br>

Open `sdk\customer\boards\Kconfig_lcd` with a text editor and add a DPI screen option and resolution as follows<br>

<br>

LCD_HOR_RES_MAX set to the screen’s horizontal resolution¶

default 720 if LCD_USING_TFT_NV3052C

LCD_VER_RES_MAX set to the screen’s vertical resolution¶

default 720 if LCD_USING_TFT_NV3052C

LCD_DPI pixel density, the number of pixels per inch on the screen, if unknown, use the default 315¶

default 315 if LCD_USING_TFT_NV3052C

2) Add LCD_USING_NV3052C<br>

Open the file `sdk\customer\peripherals\Kconfig` with a text editor and add the following<br>

config LCD_USING_NV3052C # add this configuration so it can be selected in Kconfig bool default n

<br>

3) Modify SConscript<br>

Open the file `customer\peripherals\dpi_nv3052c\SConscript` with a text editor and modify the macro `LCD_USING_NV3052C`, so that the *.c and *.h files in this directory can be included in the compilation<br>

<br>

### 2.3 Menuconfig Select NV3052C

After completing the above steps, enter the following command in the compilation window and select the newly added nv3052c screen<br>

> `menuconfig --board=em-lb566` (open the menuconfig window)

In this path `(Top) → Config LCD on board → Enable LCD on the board → Select LCD` select the newly added screen. If the DPI screen requires SPI initialization, select `lcd init using soft spi interface` and configure the three SPI IO pins. After saving and exiting, the screen driver in the `dpi_nv3052c` directory will be included in the compilation<br>

<br>

## 3 Generate SourceInsight Project

To facilitate viewing the code files included in the compilation, you can generate a list of files in the rt-driver project and import them into Source Insight. You can skip this section.

### 1 Generate File List

Run the command `scons --board=em-lb566 --target=si` to generate `si_filelist.txt`<br>

<br>

### 2 Import File List

Open Source Insight and import `si_filelist.txt` into the project<br>

<br>

### 3 Check if the Screen Driver is Effective

In the SI (Source Insight) project, check if the corresponding macros in `rtconfig.h` are generated and if `dpi_nv3052c.c` is included in the compilation

<br>

## 4 Screen Hardware Connection

### 4.1 Ribbon Cable Connection

If you have a matching screen module, simply connect the ribbon cable to the socket<br>

### 4.2 Flywire Connection

If the new screen module has a different ribbon cable arrangement, you will need to design a ribbon cable adapter or use flywires for debugging.

You can refer to the [SF32LB52-DevKit-LCD Adapter Guide](../../board/sf32lb52x/SF32LB52-DevKit-LCD-Adapter.md#qspi-lcd接口转接板) for designing the adapter board

## 5 Screen Driver Configuration

### 5.1 Default IO Configuration

If you are using the default IO, you can skip this section

#### 5.1.1 IO Mode Setting

The LCD uses LCDC1 hardware to output waveforms, and must be configured to the corresponding FUNC mode,<br>

Refer to the hardware documentation [Download SF32LB56X_Pin_config](./assets/SF32_LB56_MOD_pinconfig_20240717.xlsx) for the functions of each IO<br>

<br>

The RESET pins for the LCD and TP are configured as GPIO mode by default. If the LCD power needs to be turned on separately, it should also be configured here.

```c

void BSP_LCD_PowerUp(void)

{

#ifdef BSP_LCDC_USING_DPI

HAL_PIN_Set(PAD_PA13, LCDC1_DPI_R1, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA14, LCDC1_DPI_R0, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA16, LCDC1_DPI_R2, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA19, LCDC1_DPI_R4, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA24, LCDC1_DPI_R3, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA21, LCDC1_DPI_R5, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA23, LCDC1_DPI_R6, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA25, LCDC1_DPI_R7, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA28, LCDC1_DPI_G0, PIN_NOPULL, 1); HAL_PIN_Set(PAD_PA29, LCDC1_DPI_G5, PIN_NOPULL, 1); HAL_PIN_Set(PAD_PA30, LCDC1_DPI_G1, PIN_NOPULL, 1); HAL_PIN_Set(PAD_PA32, LCDC1_DPI_G2, PIN_NOPULL, 1); HAL_PIN_Set(PAD_PA33, LCDC1_DPI_G3, PIN_NOPULL, 1); HAL_PIN_Set(PAD_PA34, LCDC1_DPI_G4, PIN_NOPULL, 1); HAL_PIN_Set(PAD_PA31, LCDC1_DPI_G6, PIN_NOPULL, 1); HAL_PIN_Set(PAD_PA35, LCDC1_DPI_G7, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA36, LCDC1_DPI_B0, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA37, LCDC1_DPI_B1, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA38, LCDC1_DPI_B2, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA41, LCDC1_DPI_B4, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA43, LCDC1_DPI_B3, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA39, LCDC1_DPI_B5, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA40, LCDC1_DPI_B6, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA46, LCDC1_DPI_B7, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA42, LCDC1_DPI_VSYNC, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA44, LCDC1_DPI_HSYNC, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA45, LCDC1_DPI_CLK, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PA47, LCDC1_DPI_DE, PIN_NOPULL, 1);

HAL_PIN_Set(PAD_PB35, GPIO_B35, PIN_NOPULL, 0); // tp reset

HAL_PIN_Set(PAD_PA50, GPIO_A50, PIN_NOPULL, 1); // lcd reset

HAL_PIN_Set(PAD_PA51, GPIO_A51, PIN_NOPULL, 1); // tp INT,

#ifdef LCD_USING_SOFT_SPI HAL_PIN_Set(PAD_PA02, GPIO_A2, PIN_NOPULL, 0); // soft spi cs HAL_PIN_Set(PAD_PA17, GPIO_A17, PIN_NOPULL, 1); // soft spi clk HAL_PIN_Set(PAD_PA18, GPIO_A18, PIN_PULLUP, 1); // soft spi mosi #endif

#endif /* BSP_LCDC_USING_DPI */

#ifdef PMIC_CTRL_ENABLE pmic_device_control(PMIC_OUT_1V8_LVSW100_4, 1, 1); // LCD_1V8 power pmic_device_control(PMIC_OUT_LDO30_VOUT, 1, 1); // LCD_3V3 power #endif /* PMIC_CTRL_ENABLE */

#ifdef LCD_VCC_EN

BSP_GPIO_Set(LCD_VCC_EN, 1, 0); // If LCD power supply needs to be turned on, add it here

#endif /* LCD_VCC_EN */

#ifdef LCD_VIO_EN

BSP_GPIO_Set(LCD_VIO_EN, 1, 0);

#endif

}

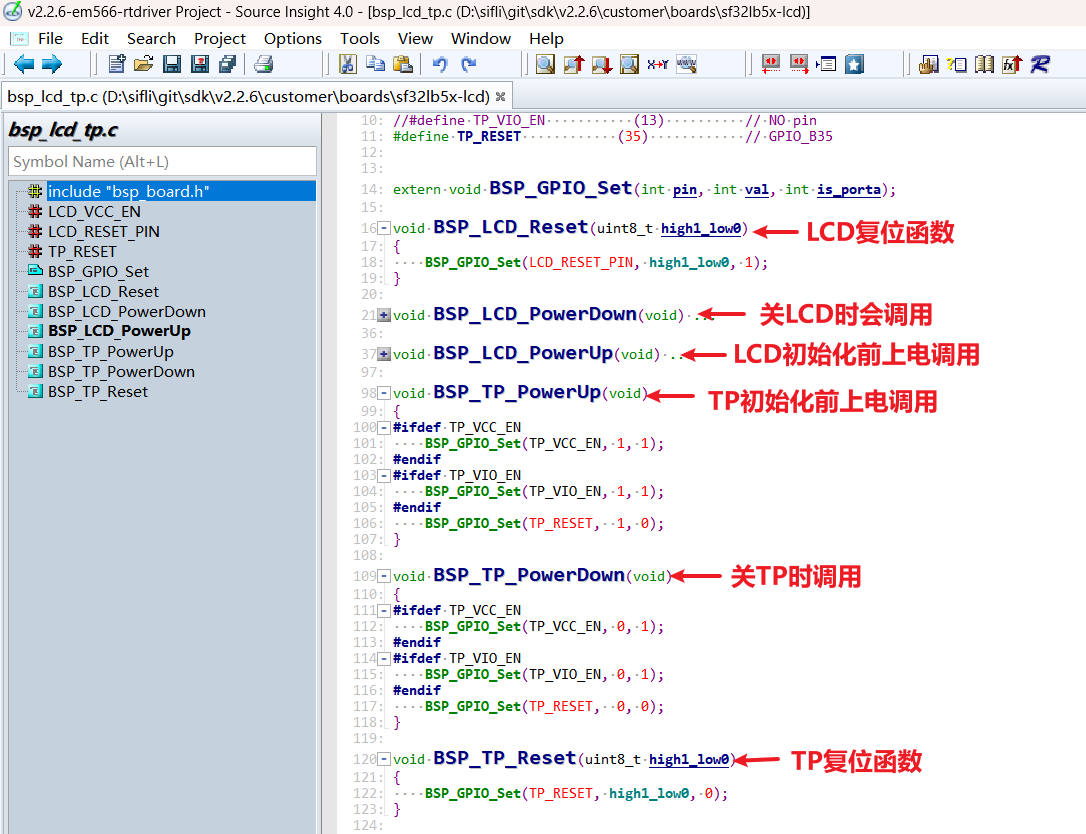

5.1.2 IO Power-On/Power-Off Operations¶

Below is the LCD initialization process during power-on:

rt_hw_lcd_ini->api_lcd_init->lcd_task->lcd_hw_open->BSP_LCD_PowerUp-find_right_driver->LCD_drv.LCD_Init->LCD_drv.LCD_ReadID->lcd_set_brightness->LCD_drv.LCD_DisplayOn

It can be seen that BSP_LCD_PowerUp is executed before the screen driver initialization LCD_drv.LCD_Init.

Therefore, before initializing the LCD, ensure that BSP_LCD_PowerUp has already turned on the LCD power supply.

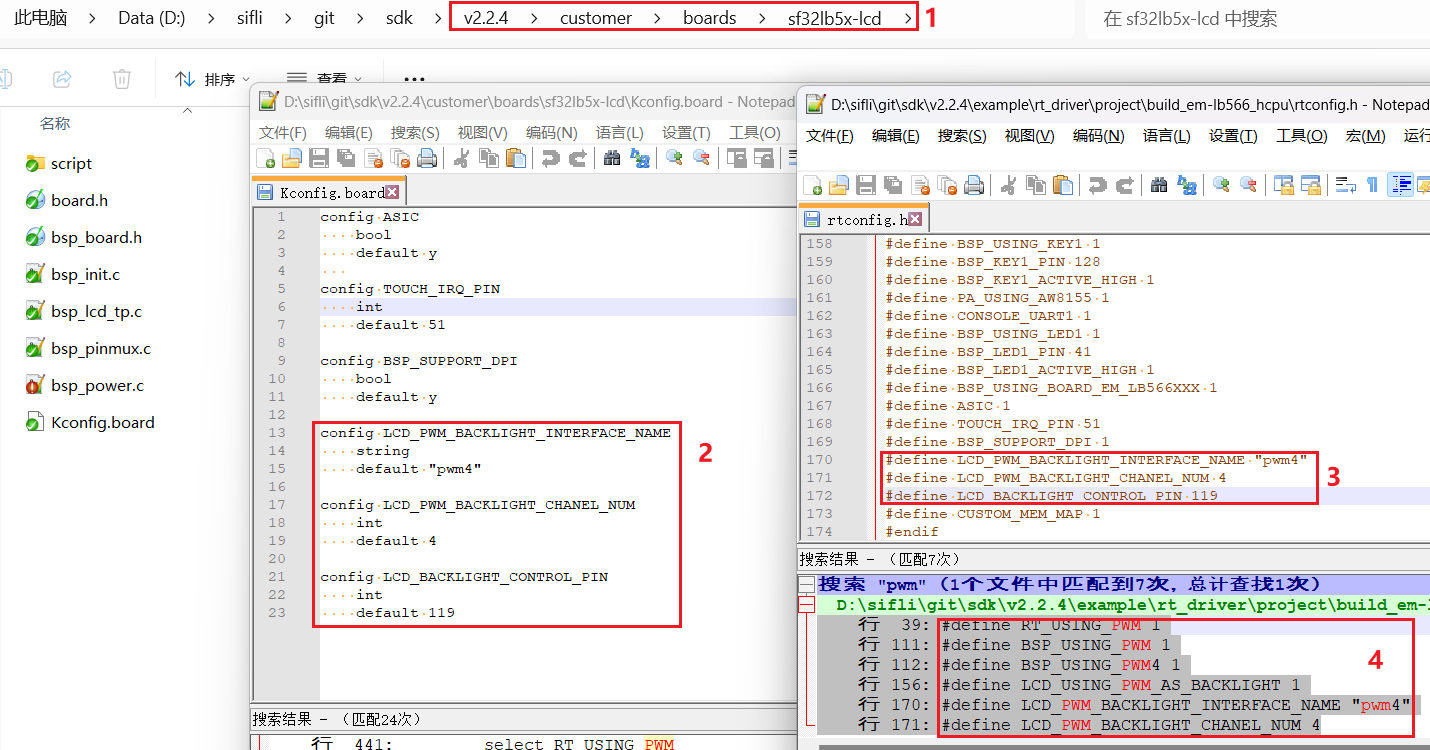

5.1.3 Backlight PWM Configuration¶

The PWM software has a default configuration, which is set in the file customer\boards\sf32lb5x-lcd\Kconfig.board. This Kconfig.board configuration will generate the following three macros in rtconfig.h after compilation:

// PWM4 requires GPTIM3 to be enabled. The correspondence between PWM and TIMER can be found in the PWM section of the FAQ or in the file `pwm_config.h`

#define LCD_PWM_BACKLIGHT_INTERFACE_NAME "pwm3"

#define LCD_PWM_BACKLIGHT_CHANEL_NUM 4 // Channel 4

#define LCD_BACKLIGHT_CONTROL_PIN 119 // PB23: 96+23

To use PWM4, GPTIM3 needs to be enabled, and Lcpu also needs to be enabled (otherwise, Lcpu might turn off GPTIM3). Additionally, ensure that the following macros in rtconfig.h are effective:

#define BSP_USING_GPTIM3 1 // If using PWM3, enable it via menuconfig --board=em-lb566

#define RT_USING_PWM 1

#define BSP_USING_PWM 1

#define BSP_USING_PWM4 1 // If not, enable it via menuconfig --board=em-lb566

The correspondence between pwm4 and GPTIM3 (located in Lcpu) is defined in the file pwm_config.h as follows:

#ifdef BSP_USING_PWM4

#define PWM4_CONFIG \

{ \

.tim_handle.Instance = GPTIM3, \

.tim_handle.core = PWM4_CORE, \

.name = "pwm4", \

.channel = 0 \

}

#endif /* BSP_USING_PWM4 */

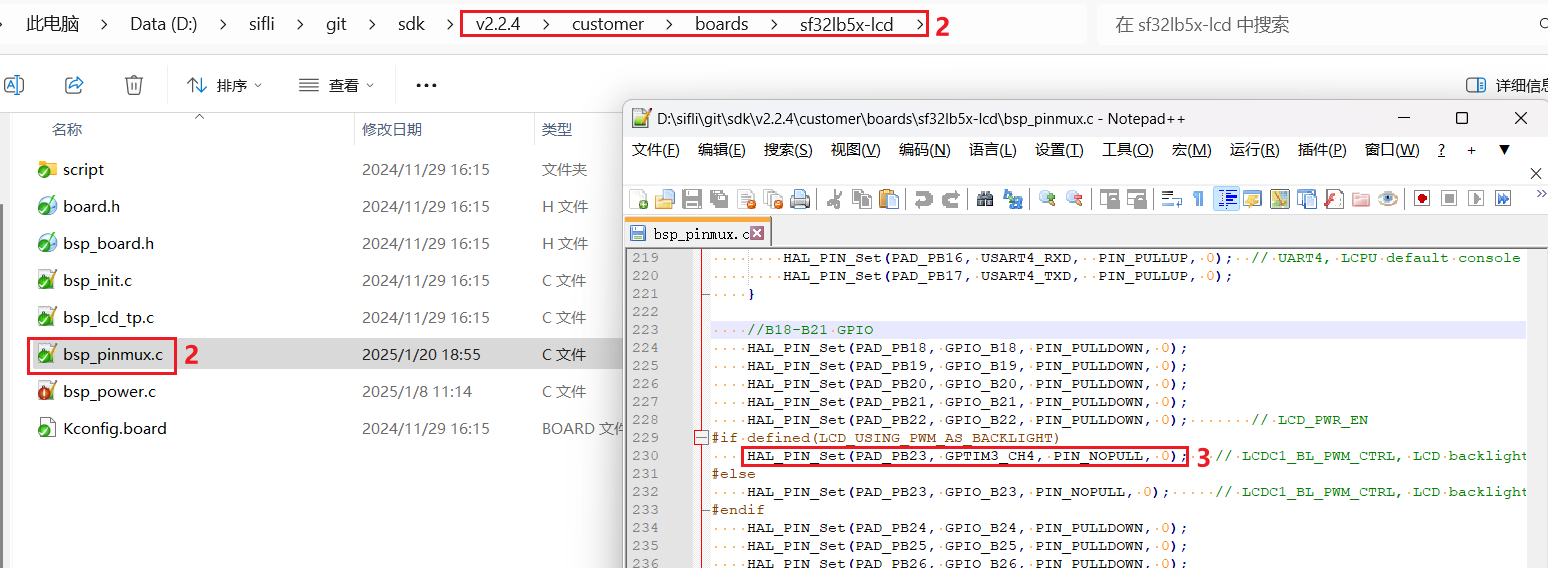

The default configuration for PB23 to output PWM waveforms from the

The default configuration for PB23 to output PWM waveforms from the GPTIM3 device is as follows:

HAL_PIN_Set(PAD_PB23, GPTIM3_CH4, PIN_NOPULL, 0); // LCDC1_BL_PWM_CTRL, LCD backlight PWM

Note:

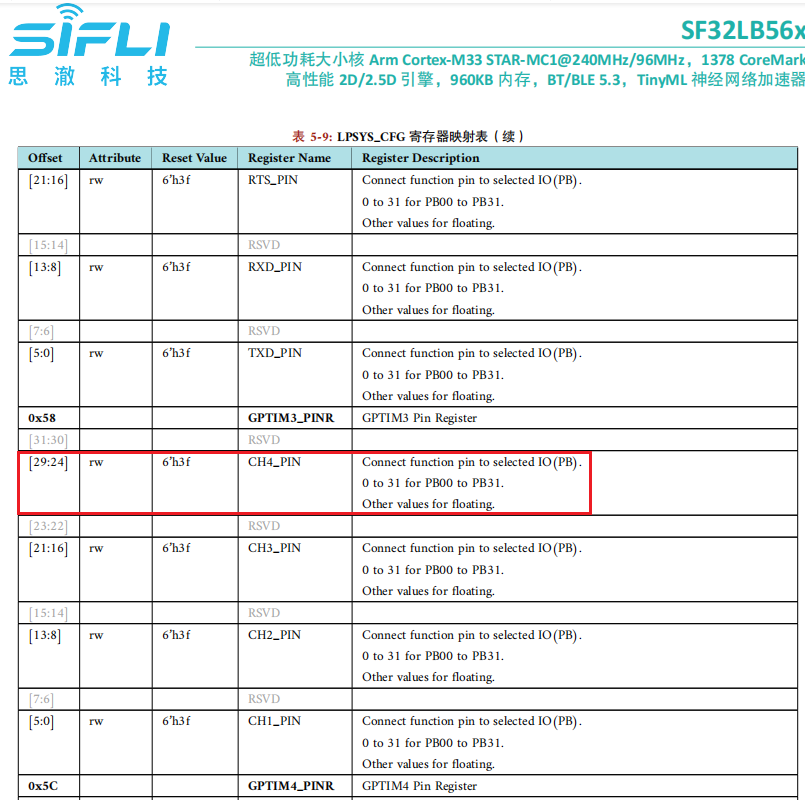

After configuring with the function HAL_PIN_Set, the correspondence between GPTIM3_CH4 and PB23 will be established, specifically in the register configuration hwp_lpsys_cfg->GPTIM3_PINR, as shown in the following figure:

It can be configured to output CH1-CH4, and it must be PB00-PB31. Additionally, Hcpu uses Lcpu’s TIMER resources, so Lcpu also needs to enable

It can be configured to output CH1-CH4, and it must be PB00-PB31. Additionally, Hcpu uses Lcpu’s TIMER resources, so Lcpu also needs to enable #define BSP_USING_GPTIM3 1, otherwise, in early SDK code drv_common.c, RCC_MOD_GPTIM3 will be disabled, leading to no output from PWM4.

#if !defined(BSP_USING_GPTIM3) && !defined(BSP_USING_PWM4)

HAL_RCC_DisableModule(RCC_MOD_GPTIM3); // Disable the clock for GPTIM3

#endif /* !BSP_USING_GPTIM3 */

5.2 LCD Driver Reset Timing¶

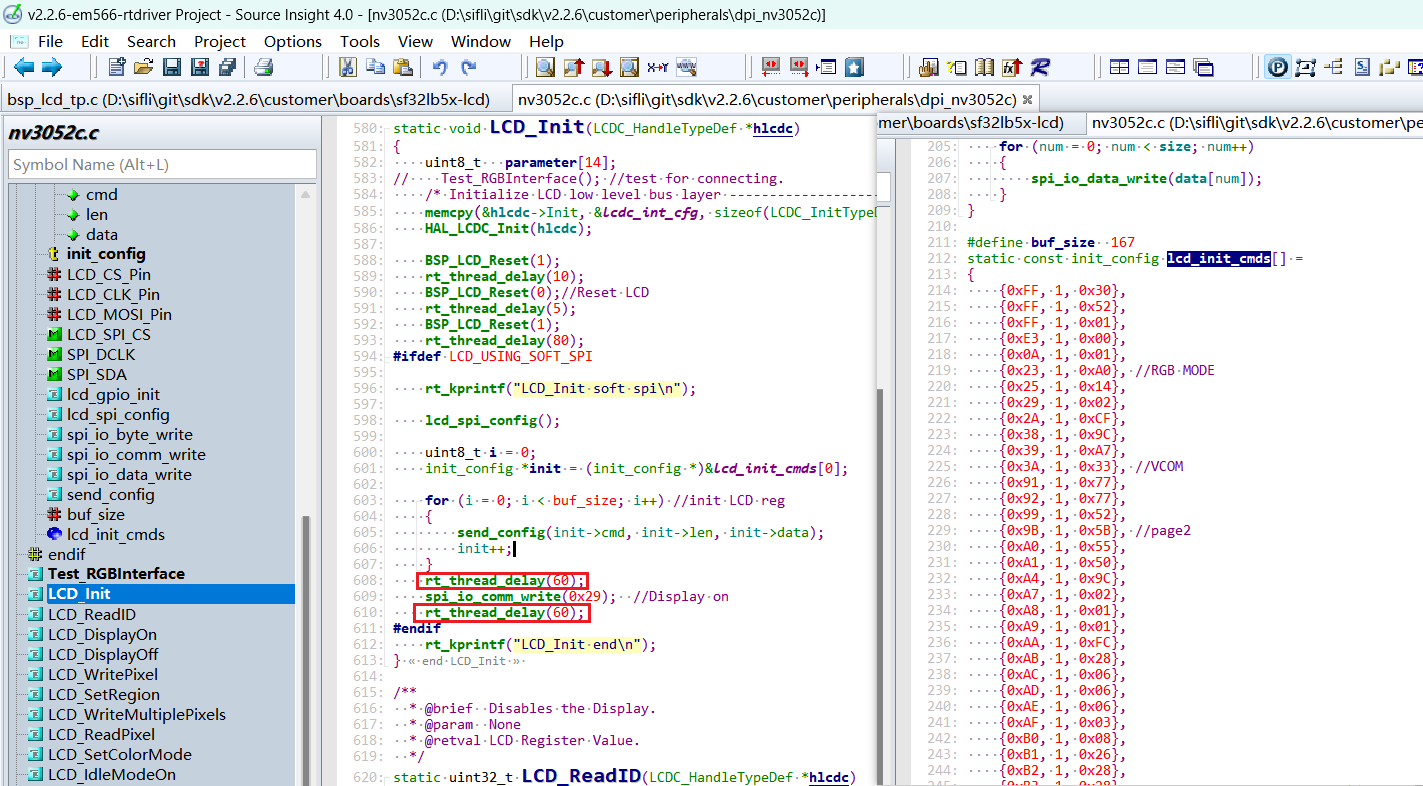

In the LCD_Init function of nv3052c.c, the following delays are critical and should be carefully modified according to the initialization timing sequence of the screen driver IC:

BSP_LCD_Reset(1);

rt_thread_delay(10);

BSP_LCD_Reset(0); // Reset LCD

rt_thread_delay(5);

BSP_LCD_Reset(1);

rt_thread_delay(80);

5.3 LCD Driver Register Modifications¶

For DPI interface screens that do not require SPI initialization, the macro LCD_USING_SOFT_SPI does not need to be enabled. After the screen driver IC is powered on and reset, data can be sent to the RGB data lines. Some DPI screens require SPI interface for register initialization configuration parameters. The initialization register configuration for each screen driver IC is different and must be written to the screen driver IC according to the SPI timing sequence provided by the screen manufacturer. Pay special attention to the delay requirements after writing to registers 0x11 and 0x29.

static void LCD_Init(LCDC_HandleTypeDef *hlcdc)

{

...

#ifdef LCD_USING_SOFT_SPI

rt_kprintf("LCD_Init soft spi\n");

lcd_spi_config();

uint8_t i = 0;

init_config *init = (init_config *)&lcd_init_cmds[0];

for (i = 0; i < buf_size; i++) // init LCD reg

{

send_config(init->cmd, init->len, init->data);

init++;

}

rt_thread_delay(60);

spi_io_comm_write(0x29); // Display on

rt_thread_delay(60);

#endif

rt_kprintf("LCD_Init end\n");

}

5.4 Screen Driver Parameter Configuration¶

.lcd_itf: Select

LCDC_INTF_DPI_AUXto indicate DPI interface mode.freq: Select

35 * 1000 * 1000, indicating the DPI clk frequency is 35 MHz. This clock should be chosen based on the highest clock supported by the screen driver IC. The higher the clock, the shorter the time to send each frame, and the higher the frame rate..color_mode: Choose between

RGB565andRGB888format

static LCDC_InitTypeDef lcdc_int_cfg =

{

.lcd_itf = LCDC_INTF_DPI_AUX,

.freq = 35 * 1000 * 1000,

.color_mode = LCDC_PIXEL_FORMAT_RGB888,

.cfg = {

.dpi = {

.PCLK_polarity = 0,

.DE_polarity = 0,

.VS_polarity = 1,

.HS_polarity = 1,

.PCLK_force_on = 0,

.VS_width = 5, // VLW

.HS_width = 2, // HLW

.VBP = 15, // VBP

.VAH = 720,

.VFP = 16, // VFP

.HBP = 44, // HBP

.HAW = 720,

.HFP = 44, // HFP

.interrupt_line_num = 1,

},

},

};

5.4 RGB Interface Flywire Test Function¶

If you are debugging with flywires, there are many RGB data lines, and incorrect wiring can lead to no display or abnormal display. You can use the following test function for the RGB interface, which outputs waveforms in the order of R0-R7, G0-G7, B0-B7. You can use a logic analyzer to capture the waveforms to check if the flywires are correct.

Test_RGBInterface(); // test for connecting.

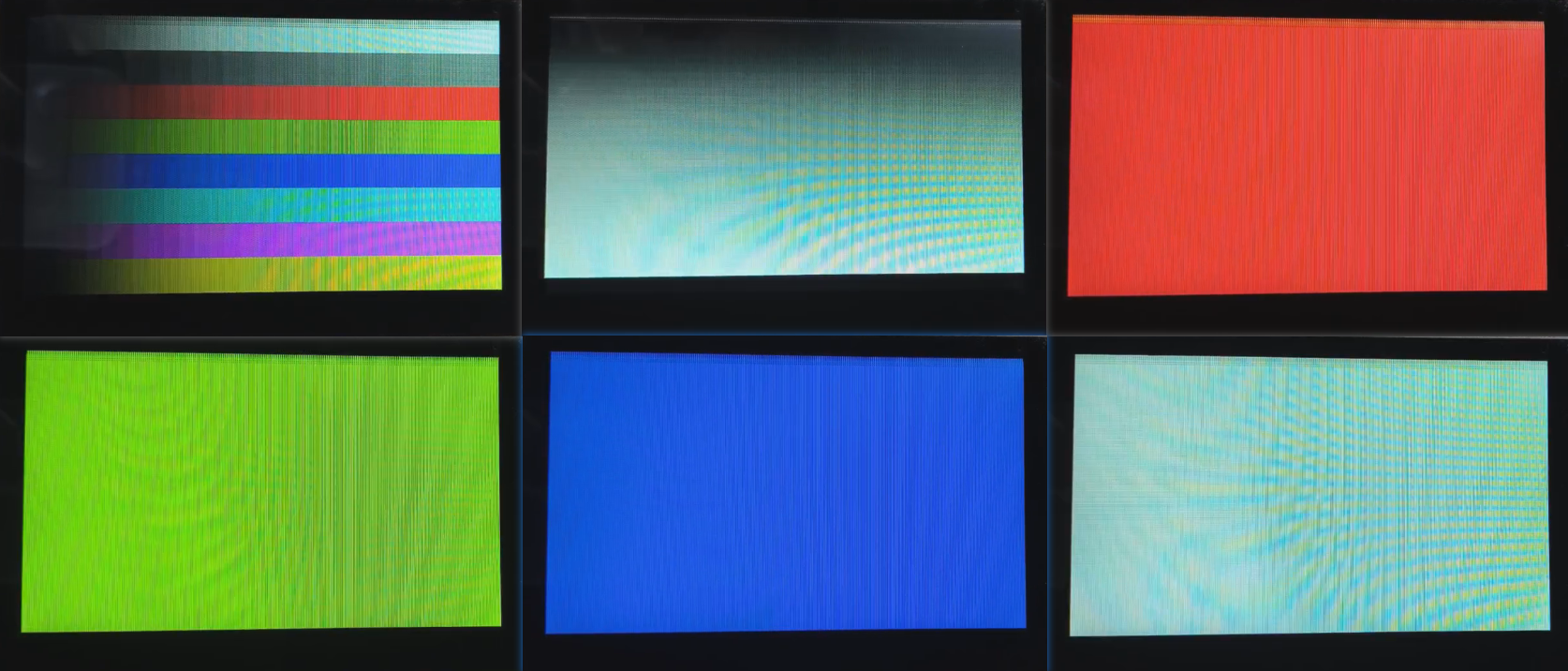

6 Compilation and Download Results¶

6.1 Display Result Demonstration¶

As shown in the figure below, if the display is normal, it will show six images in sequence, with a 3-second timer loop.