4 Common Issues in Motor Debugging¶

4.1 Configuration for GPIO Simulating Motor Vibration¶

Considering the use of any IO port to drive the motor, the solution code implements the GPIO-driven motor code. The macro definitions in rtconfig.h after menuconfig configuration are as follows:

#define MOTOR_ENABLED 1 // Enable motor

/* MOTOR_USE_PWM is not set */

#define MOTOR_PERIOD 200 // Motor vibration period

#define MOTOR_POWER_IO -1 // Motor power on, set to -1 if no power control is configured

#define MOTOR_SW_CONTRL 1 // Enable software control of the motor

#define MOTOR_CTRL_IO 121 // Configure as 121-96 = PB25 as the motor drive port

You can use the following test code to test the motor function:

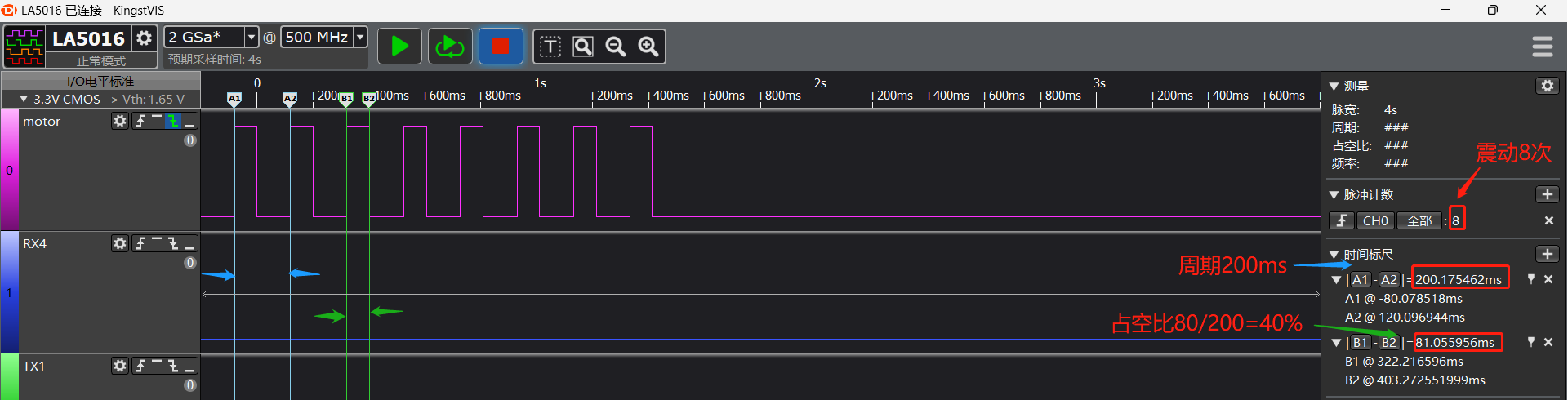

finsh serial command: motor set 1 8 4

Parameters: 1 represents starting the motor, 8 represents vibrating 8 times, 4 represents 40% duty cycle.

The actual drive waveform is shown in the following figure:

#ifdef RT_USING_FINSH

int motor(int argc, char **argv)

{

char i;

if (argc > 1)

{

if (strcmp("on", argv[1]) == 0)

{

rt_kprintf("motor on!\n");

app_start_motor();

app_set_motor_level(MOTOR_TEN_LEVEL);

}

else if (strcmp("off", argv[1]) == 0)

{

rt_kprintf("motor off!\n");

app_stop_motor();

}

else if (strcmp("set", argv[1]) == 0)

{

uint32_t mode = strtoul(argv[2], 0, 16);

uint32_t time = strtoul(argv[3], 0, 16);

uint32_t level = strtoul(argv[4], 0, 16);

rt_kprintf("turn on mode:%d,time:%d,level:%d\n", mode, time, level);

app_set_motor_level(level);

app_motor_control(mode, time);

}

else

{

rt_kprintf("command is err!\n");

rt_kprintf("example:\n motor on\n motor off\n motor set 1 50\n");

}

}

return 0;

}

MSH_CMD_EXPORT(motor, forward motor command); /* Export to msh command list */

#endif

The corresponding duty cycle levels are:

const app_motor_grade_t g_motor_level[MOTOR_MAX_LEVEL - 1] =

{

{MOTOR_PERIOD, MOTOR_PERIOD / 10},

{MOTOR_PERIOD, (MOTOR_PERIOD / 10) * 2},

{MOTOR_PERIOD, (MOTOR_PERIOD / 10) * 3},

{MOTOR_PERIOD, (MOTOR_PERIOD / 10) * 4},

{MOTOR_PERIOD, (MOTOR_PERIOD / 10) * 5},

{MOTOR_PERIOD, (MOTOR_PERIOD / 10) * 6},

{MOTOR_PERIOD, (MOTOR_PERIOD / 10) * 7},

{MOTOR_PERIOD, (MOTOR_PERIOD / 10) * 8},

{MOTOR_PERIOD, (MOTOR_PERIOD / 10) * 9},

{MOTOR_PERIOD, (MOTOR_PERIOD / 10) * 10},

};